Articles

TVA Is Vibrating Its Ash

There is a low thrum happening at TVA’s Kingston Fossil Plant, near Harriman, Tenn. It’s not perceptible to the human ear, and it isn’t a problem; it’s a solution. This “good vibration” stems from TVA pioneering an industry-leading technology to more safely store dry coal ash.

“I’m building a mountain of ash—one layer at a time,” says Jason Hill, TVA environmental scientist and program manager for Risk and Quality Assurance at the Kingston Fossil Plant intelligent compaction project. “Over the next 40 years we will stack ash layer on top of layer until the rock-hard mound looks like a step pyramid.”

Coal ash is the by-product of burning coal for electricity. TVA recycles 33 percent of its coal ash; which goes into common building materials like concrete, roof shingles and wallboard.

Ash that cannot be recycled must be stored. That is where Hill’s team of engineers gets involved.

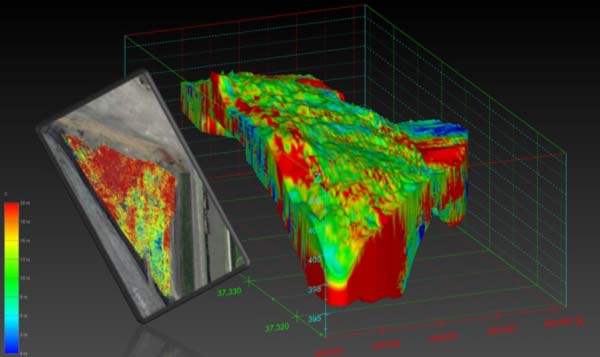

Compaction is mapped in real-time. Engineers analyze the data to ensure the compaction meets specifications.

“Ash safety is our priority at TVA,” explains Hill. “Today we have more than 7,000 sensors monitoring our coal ash 24/7/365, which are networked to our coal ash monitoring center. We are closing all our wet ash storage impoundments over the next four to six years. Also, the new ash compaction technology will allow us to prevent safety and environmental issues.”

A New Way to Store Coal Ash

For decades the utility industry stored coal ash in ponds—but later discovered that they risked structural instability and surface and groundwater contamination if not properly managed. The advent of dry ash containment dramatically reduces these environmental and safety risks.

Today, TVA’s Kingston Fossil Plant is the model for ash storage because the technology TVA is using increases coal ash storage safety and efficiency.

“Think of dry ash storage as a parking lot,” says Hill. “We wet the ash and mix it to the consistency of cookie dough. Then we lay ash down like pavement and compact it to a density of 95% or greater.”

As ash is laid down, heavy rolling machines drive over it to compact it, much like you would see on a road paving project. The compacting machine is equipped with a vibrating drum and sensors that send data directly to the operator and TVA engineers in real-time.

Hill notes that the array of sensors outfitted to the compacting machine is the game changer. “We see what the driver is doing in real-time,” says Hill. “If an area needs more compaction, I can immediately send the driver back over the area. It’s state-of-the-art.”

Traditionally Hill and other TVA engineers would have to be at the site to observe and test the material. Now Hill can monitor the ash and the compaction rates from his office in Chattanooga, Tenn.—over 100 miles away from TVA’s Kingston facility.

Breaking New Ground

“From my desk I can monitor every TVA ash site with confidence and apply best practices to each location,” says Hill. “No other company in the utility industry is doing this with this level of detail.” While compaction technology is used in road construction, TVA is the first utility in the United States and possibly the world to apply it to coal ash.

According to TVA, the new compaction technology will cost around one million dollars to outfit each facility and far exceeds state and federal monitoring standards. But the rewards in safety and long-term cost savings far outweigh the startup costs. “The tighter we pack it, the more we can safely store, which saves ratepayers money,” adds Hill.

It will take 40 years to complete the Kingston ash stack. During that time, TVA will create a 3-D compaction map of each layer that engineers can analyze for years to come.

“The 3-D technology far exceeds state and federal monitoring standards because we can monitor 100 percent of the ash stack for the life of the project,” Hill says.

Now that the technology has been proven at Kingston, it is being applied at other TVA storage sites across the Valley. Bull Run Fossil Plant, located near Knoxville, Tenn., is already using the equipment.

24/7 Safety

To reduce the risk of structural instability and surface and groundwater contamination, TVA is closing all of its wet coal ash impoundments. Sensors are placed at these impoundments to ensure safety. The sensors are monitored around the clock and data is fed into the company’s ash monitoring center in Chattanooga, Tenn.

“With a few clicks we can pull up sensor data and see real-time data or watch what’s happening at our impoundments or look at live video,” says Hill. “What’s most important is that we can share information with everyone who is working the problem.”

Hill believes that all of these safety efforts have made TVA the industry leader in the safe, responsible coal ash storage.